Bolon Island Move

“We’ve really outgrown the old boatyard. Having just one ways really slows us down,” stated Fred’s son Mike Wahl. “On the new property we will be able to haul a large number of boats and move them under cover for painting, major repairs, sponsons, mid-bodies, or deck modifications,” he explained. The Bolon Island property is close to the existing yard by water and 8 miles upstream from the port of Winchester Bay at the mouth of the river. It is also adjacent to the main coastal road-Highway 101.

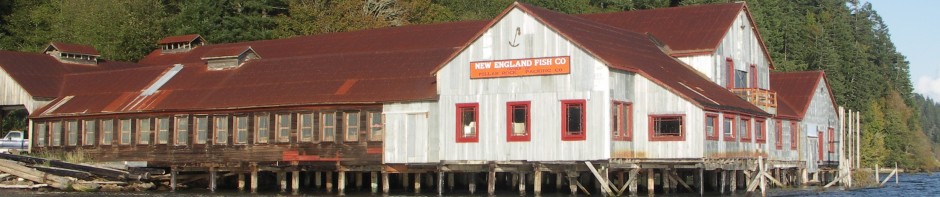

The American Bridge Company invested $10 million here to build a state-of-the-art facility in 2000, but was forced to close in 2013. Wahl saw this as a huge opportunity and was able to purchase it in 2014. The property came with two large structures: a 50,000 sq. ft. fabrication building with overhead cranes, and a 12,000 sq. ft. paint shop. The plan was to develop a new haul-out and storage facility with major production and conversion under cover. Other features on the island will be a wash-down area with self-contained drainage, a 190-foot by 64-foot fixed pier with an additional 200 feet of floating dock. Water depth in the river is around 20 feet.

Last winter, during the short in-water work window allowed to protect migrating salmon, West Coast Contractors of Coos Bay dredged the short channel into the lifting dock with a 90-ton crane on a barge. Then they drove 800 feet of sheet piling connected to an anchor wall with tie rods. A total of 74 pipe piles of 24-inch diameter were driven to a maximum depth of 150 feet to support the two runways the new boat lift will use. The Ascom marine lifter is built in Italy and is scheduled to arrive in September. It has a 660-ton capacity and can lift vessels with a maximum beam of 42 feet. The standard design includes four-wheel drive with all-wheel steering and a built-in digital weigh scale.

With more than 30 acres available for boat storage onshore, Jim Zimmer, a project manager with the company, estimates the repair and maintenance work could increase by 50 percent, requiring about 40 new hires. “Overall, the new yard means more efficiency and a faster turnaround,” he explained. “This is a big selling point these days!” This should increase revenue by at least one third, he estimates, and provide a welcome boost to the local economy, which has been badly hit by the decline in timber harvests. The expanded shipyard will enable the yard to haul a large number of boats and move them under cover for painting, major repairs, sponsons, mid-bodies, or deck modifications.

With the boat lift scheduled to arrive in Reedsport September 5, the company has already started moving operations across the river. Haul-outs at the new facility are expected to start on Bolon Island toward the end of September. By August, all of the office staff had re-located to the new offices on the Island and were back to work. In the big fabrication shop, work was well under way on a new 58-foot combination boat.

Like wood products, the fishing business on the West Coast has changed dramatically since the 1980’s, and this expansion plan goes against the tide of declining fleets and catches. But Wahl has shown his ability to survive and prosper where others have failed. Since 2000, his crew has been on a tear, delivering about 70 percent of all the new fishing vessels 58 feet and longer for Alaskan waters. “We build more commercial fishing boats here over 50 feet than anywhere else in the United States,” Wahl says with pride.

FRED WAHL was born in Depoe Bay in 1947, and has spent most of his life on the Oregon Coast. He left home at a young age to work in the fishing industry, where he learned to repair fishing vessels of all types. He moved back to his hometown to build his first boat the 58-foot F/V Cindria Jean. Despite the fact that this hole-in-the-wall port is famous as the “smallest harbor in the world,” he didn’t start small: his third build was a 58-foot seiner-combination boat named F/V St. Patrick for Mark Anderson of Friday Harbor, Washington.

Mark fished it until 2002 when he sold it to the University of Washington who converted it into a research vessel. He ran it as an “R/V” for eight years until he decided to get back into fishing by buying into a new Wahl boat, the 58-foot by 22.5-foot F/V Loui M. The fourth and last boat Wahl built in Depoe Bay was another 58-footer, launched in 1991. All of these craft were built in a pole-building shop and trailered down to the ramp at the back of the tiny cove. By then, Wahl boats were already making waves and it was time to move up to a 7-acre vacant boatyard in Reedsport, 85 miles to the south.

The port owned the property and Wahl leased it for the first few years, while his crew did a lot of overdue maintenance to the 900-ton marine railway. This enabled them to haul vessels up to 170 feet, and slide one to each side of the tracks for more long-term work. Dockside they could handle big trawlers up to 200 feet, but there wasn’t much new construction going on in the 1990’s, so they only picked up eight orders in the first decade. “All through the ’90s it was really slim,” Wahl recalled. However, he was confident enough to purchase the yard anyway.

When times were slack, he had his crew would work on the site, building new shops for fabrication, machine, paint, electrical, hydraulic and carpentry work. Eventually, the team of skilled machinists was able to begin building from scratch most of the equipment that would be needed to fit out the typical order: seine and picking booms, pot launchers, bait choppers, hydraulic-lift sorting tables, anchors and anchor winches. Since then, there has always been a large inventory of new and re-conditioned gear and parts to cover the gear for most fisheries.

The pace of new construction picked up after 2000, and since 2003 the yard has never built fewer than two boats a year, peaking with five boats in 2011. Production was aided by the introduction of modern machinery like a Plasma/Oxy CNC table and other computer-controlled tools that automated layout and cutting of all structural panels. (The yard has a full-time CAD specialist on staff.) The bigger the boat, the more labor hours can be saved by computerization. The examples that follow all relied on extensive CAD work to create the cutting files for the CNC table.

In 2013, the yard built its biggest vessel to date, the F/V Victory, a 114-foot by 31-foot combination boat with aft house based on a larger model of the 98-foot by 27-foot F/V Vixen, that was designed and built by Fred Wahl in 1998. The Victory is owned and operated by Wahl Fisheries and is distinguished by the amount of stainless steel trim fitted to reduce rust and the work needed to control it. Besides this challenging project, the crew also managed to complete three more big boats in a busy year.

Still, it’s the versatile 50- to 58-foot combo boats that fill most of the slots – almost 30 of them built from the company’s stock designs. The 58-footers have a big following in the Industry, with a great reputation for seaworthiness and beam varying from 22.5 feet to 28.5 feet to suit the owner’s needs. Typically, accommodation is in the form of one four-berth and one two-berth stateroom under the raised foredeck with a spacious galley and mess.

One of the most complete conversions they have performed started in 2014 on the F/V Miss Berdie, launched in Alabama in 1987. She came in at 77 feet long, with a 27.8-foot beam and 11.5-foot draft. Working to a plan from Hockema & Whalen, they literally took the hull apart, sponsoned it forward of the engine room, rebuilt the stern, re-shaped the bow and raised the main deck aft of the engine room. She emerged from this surgery with a length of 80.8 feet, a beam of 39 feet and her hold increased from just under 4,000 cubic feet to 7,500 cubic feet Power was upgraded to a V-16 Cummins QSK50-M1 Tier 3 delivering 1,800 HP at 1,900 RPM.

In 2015, the new owners of the 76-foot by 30-foot F/V Alpine Cove, built by Fred Wahl Marine in 2001, brought it back to the yard to increase the hold capacity. This was achieved with a mid-body extension of 6 feet, 10 inches, and a complete re-work of the deck for trawling and shrimping. It left the yard this February with a length of 83 feet and a new name – the F/V Ocean Invictus – and is now based in Warrenton, Oregon at the mouth of the Columbia River. The crew have enjoyed some good fishing off the coast this summer and between trips, they have been fine-tuning the deck gear.

At 28 feet, the beam of the F/V Insatiable is the widest 58 combo design they offer, and was built on spec. The boat was picked up by Ron Kaufman of Kodiak after he sold his share of his first Wahl-built boat, the 58-foot by 26-foot Isle Dominator launched in 2013. The yard also has a design on the drawing board to fit the under 50-foot class; it is 49.5 by 22 feet.

Alaskan Tugs a Specialty